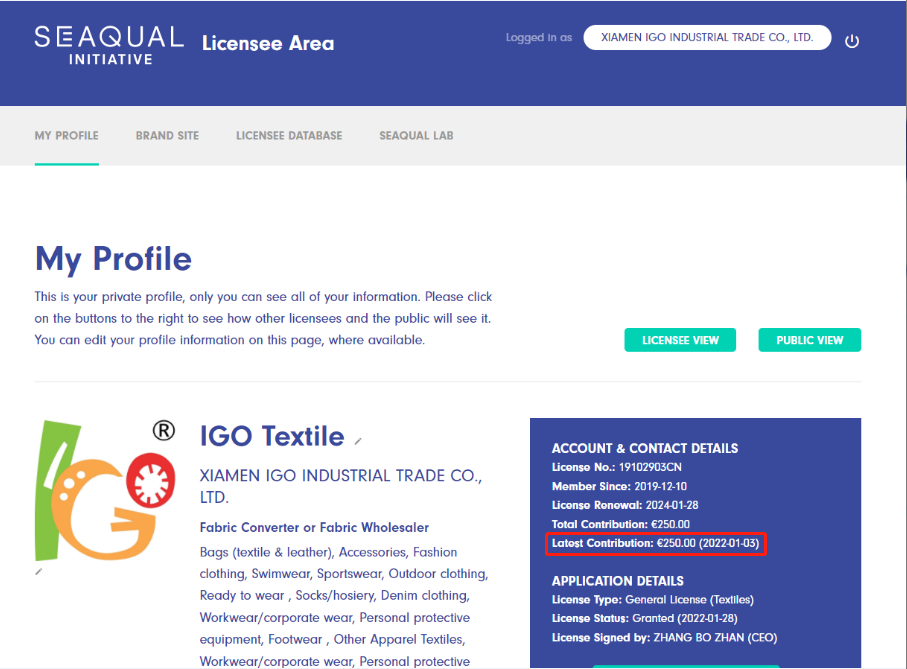

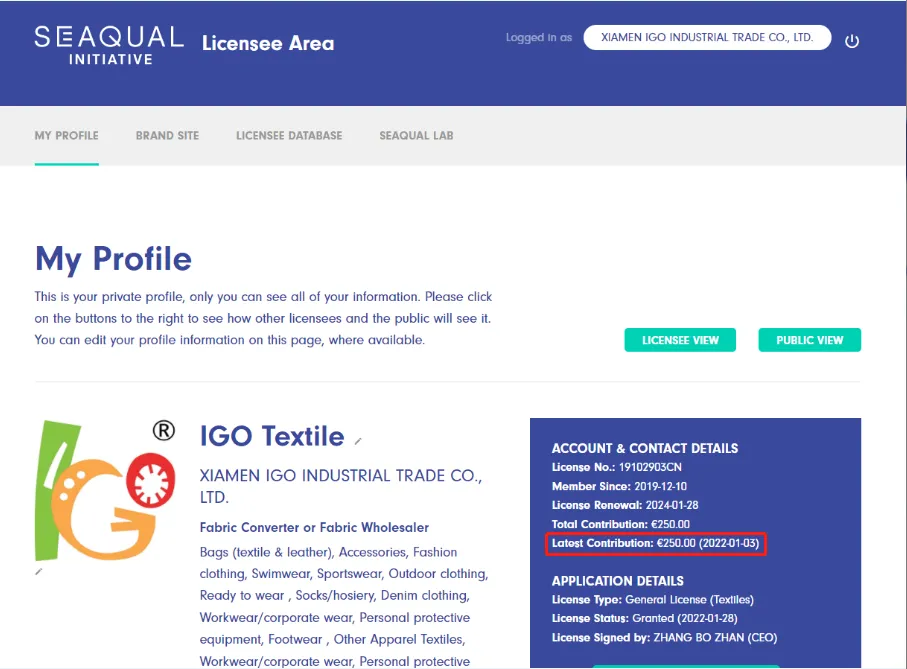

In December 2021, we made our first contribution of EUR250.00 for SEAQUAL INITIATIVE.

We are pretty proud that Xiamen IGO has become part of SEAQUAL INITIATIVE – a global community helping to clean our oceans.

SEAQUAL INITIATIVE raises awareness of the problem of marine litter and gives visibility to the many people and organizations working hard to clean our oceans.

Every year 8-12.7 million tons of waste end up in our seas, and 640 thousand tons of fishing nets are abandoned at the bottom of the ocean (data sourced from FAO and UNEP). Such alarming data tell us that, unless the situation changes, by 2050 our seas may contain more garbage than fish. We need to change our approach radically, cohabiting with Nature in the best possible way, and considering the importance of a limited resource such as water. We need to be more deeply aware of this situation and change our mentality completely.

The SEAQUAL INITIATIVE is a unique collaborative model involving NGOs, Fishermen and many more to clean the Ocean floor and surface, rivers and estuaries, beaches and coastlines. The SEAQUAL INITIATIVE transforms the sea-plastic into yarn, which is then turned into high quality materials. These materials are very versatile. For every kilogram of produced yarn, one kilogram of marine waste is recycled.

SEAQUAL YARN contains approximately 10% Upcycled Marine Plastic (from plastic marine litter), the remaining 90% is post-consumer PET from land sources. Upcycled Marine Plastic is made from marine litter retrieved from our oceans, beaches, rivers and estuaries.

SEAQUAL YARN can be blended with natural fibres or used in pure (100%) versions, either greige or yarn-dyed. They meet the requirements of bags, shoes, ready-to-wear, sportswear, denim and even swimwear. Although the SEAQUAL YARN offers identical properties and qualities to fibres created using new polyester fibre, its environmental footprint is incomparable. It plays an active role in cleaning up the ocean depths and allows for a 40% reduction in water consumption, energy savings of 50% and reduces carbon emissions by 60%.

How is SEAQUAL YARN made?

- Ocean clean-ups collect the marine litter.

- The marine litter is transported by licensed waste management companies to SEAQUAL INITIATIVE approved sorting centers.

- The waste is sorted into plastics and non-plastics.

- The plastic is sorted into different polymer types.

- Each polymer type is then compressed into ‘bales’ (a large block) for transportation.

- The ‘bales’ of PET bottles are then sent to a SEAQUAL INITIATIVE approved ‘flake’ producer.

- The ‘bales’ of PET bottles are opened, and the bottles are shredded into small pieces (‘flakes’). At this stage, other materials such as the bottle tops, labels, glues used on the labels and any residual waste, such as sand, are removed and separated in a washing process.

- The 100% PET washed ‘flakes’ are then sent to a SEAQUAL INITIATIVE approved ‘chip’ manufacturer (‘chips’ are also known as ‘pellets’ or ‘nurdles’).

- The chip manufacturer mixes the marine litter PET flakes with post-consumer PET flakes from land sources.

- The mixed ‘flakes’ are heated until molten and forced through an extruder, where long spaghetti-like ‘threads’ are formed and then chopped into small lengths or ‘chips’

- The ‘chips’ are sent to the SEAQUAL licensed yarn manufacturer.

- The SEAQUAL licensed yarn manufacturer ‘melt spins’ the polymer chips. Molten polymer is forced through a spinneret (metal block with tiny holes) and viscous threads fall by gravity, cooling as they fall. Thousands of threads are produced at the same time, with between 34 and 134 threads being used to create each yarn. The threads are combined and wound onto a bobbin at high speed (approximately 300km/h).

- The bobbins are transported to the texturing plant, where the yarn is given texture.

- The textured yarn is shipped to SEAQUAL licensed textile manufacturers.