100Dx150D waterproof RPET fabric blended with virgin poliester for autumn

IGO textile is a 100Dx150D waterproof RPET fabric blended with virgin poliester for autumn in China. We take pride in supplying fabrics made with eco-friendly and sustainable materials.We are specialized and professional in eco-friendly materials and dedicated to upgrade your products with sustainable and green fashion. We will help you develop your market by the leading edge of applying latest green materials on your products.

Delivery: EXW, FOB, CFR, CIF

Minimum order quantity: 2000 yards

Supply Ability: 100,000 yards / Month

Country of Origin: CHINA

Payment term: by T/T 30% as deposit, 70% before shipment

Lead Time: 30 Days

100Dx150D waterproof RPET fabric blended with virgin poliester for autumn supplier

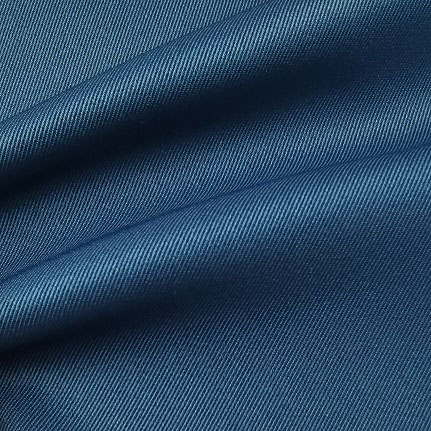

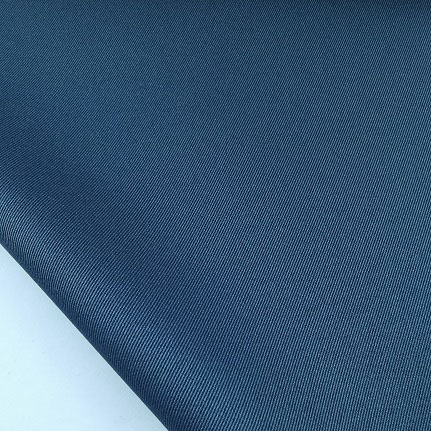

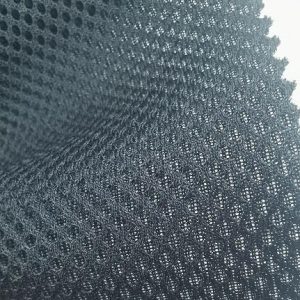

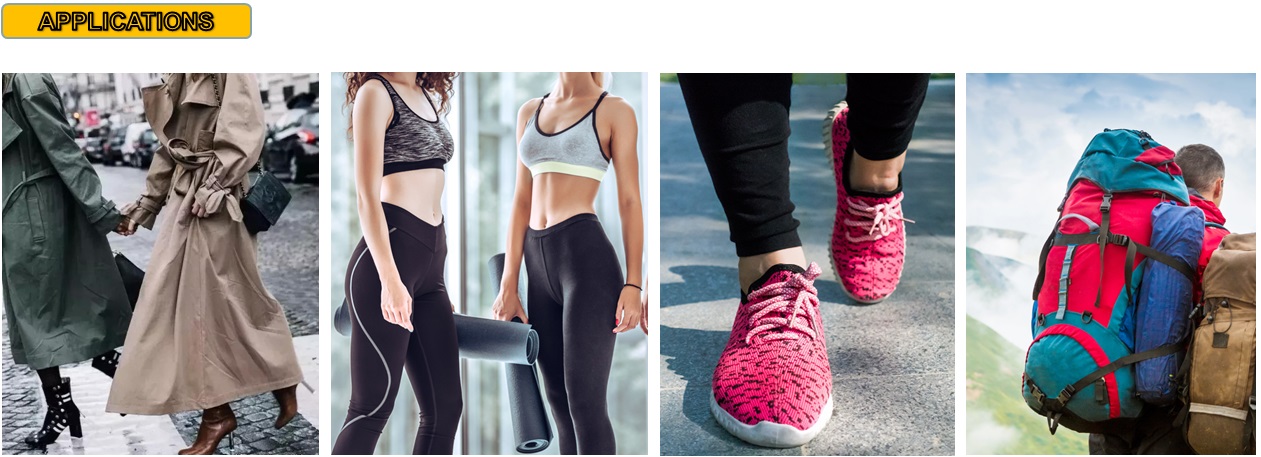

We are an innovative company of eco-friendly fabric solutions,as one of our basic fabric, 100Dx150D waterproof RPET fabric blended with virgin poliester for autumn have soft color, the composition is 65%RPET and 35%Poly, soft texture, delicate touch, high-strength wear resistance, durable, waterproof moisture-proof, quality excellent, Suitable for suits, work clothes, professional wear, high-grade clothing, business bag, home textiles and so on. The recycled polyester yarn we use is GRS (Global Recycle Standard) certified, transaction Certificate (TC) available when order, it can be customized to your requirementse, for more information welcome to contact us.

Name : 100Dx150D waterproof RPET fabric blended with virgin poliester for autumn Model no. : HYR2902 Material : polyester Composition : 65%RPET 35%Poly Specifications : 100D*150D/T400 Colour : black or tailor-made dyed Treatments : waterproof Features : waterproof fabric,100Dx150D waterproof RPET fabric mixed with virgin polyester for bags and apparel Width : 150cm GRS certificate : Transaction Certificate (TC) available when order

IGO Textile As a service-oriented company, loves making eco-friendly fabrics.

IGO Textile As a service-oriented company, loves making eco-friendly fabrics. we focus on identifying, sourcing, and supplying eco-friendly products and services to targeted market segments. We will help you develop and expand your markets by the leading edge of applying eco-friendly materials on your new products. We are passionate about what we do, yet we are also deeply aware of our responsibility. We’re having a belief in everything we do, from the way we do business to the way we treat our customers and our people, in knowing that what we do affects the planet. We hope to become a renowned OEM supplier and advisor helping our customers achieve their environmental goals in procurement.

How should fabric do waterproof finish /Water-repellent finish?

Water-repellent finish: the hydrophilic surface of the fiber becomes hydrophobic, so that the fabric is breathable and not easy to be wet by water. After the waterproof finishing textile can resist rain, oil stains, and can let the sweat of human body, sweat out in time, so as to keep the human body comfortable, dry and warm.

1、preparation

First, check whether the fabric itself has done other special finishing, such as holy soft, stiff, flame retardant and other functional products.

Second, look at the impact of impurities. One is the impurities of the fabric itself, cotton cloth surface will have cotton seed crumbs and other small impurities, chemical fiber surface impurities will be relatively little, mainly late processing residual trace oil and alkaline substances. The second is foreign impurities, mainly refers to the fabric in the pretreatment, dyeing and other additives to add residual dry fabric surface.

2、Process formula test

First, choose auxiliaries. About how to choose additives to do waterproof finishing, mainly depends on the requirements of customers, the situation of fabrics and customers’ existing process equipment. Recommend the most suitable auxiliaries for small sample and medium sample testing to ensure the effect

Next, determine the dosage. Test to determine the optimal amount of waterproofing to meet customer requirements.

Finally, the process is determined. Many customers report that the waterproof effect can be tested in the laboratory, but the reproducibility of the waterproof effect on the large machine is low. So, in this case, we mainly start from the baking effect, the baking effect is nothing more than temperature, time and thermal efficiency of equipment. Whether it is a large machine or a small laboratory equipment, the thermal efficiency can not be adjusted, only from the temperature and time, fixed temperature, the time is extended, or the time is constant, the temperature is increased.