recycled PET 150D anti-wrinkle twill gray poliester fabric for autumn fall

IGO textile is a recycled PET 150D anti-wrinkle twill gray poliester fabric for autumn fall wholesaler. As a service-oriented company, we focus on identifying, sourcing, and supplying eco-friendly products and services to targeted market segments. We are specialized and professional in eco-friendly materials and dedicated to upgrade your products with sustainable and green fashion. We will help you develop your market by the leading edge of applying latest green materials on your products.

Delivery: EXW, FOB, CFR, CIF

Minimum order quantity: 2000 yards

Supply Ability: 100,000 yards / Month

Country of Origin: CHINA

Payment term: by T/T 30% as deposit, 70% before shipment

Lead Time: 30 Days

recycled PET 150D anti-wrinkle twill gray poliester fabric for autumn fall wholesaler

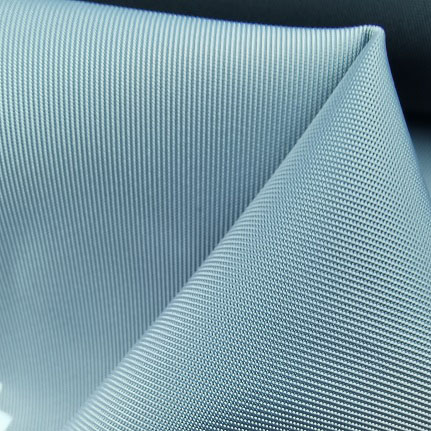

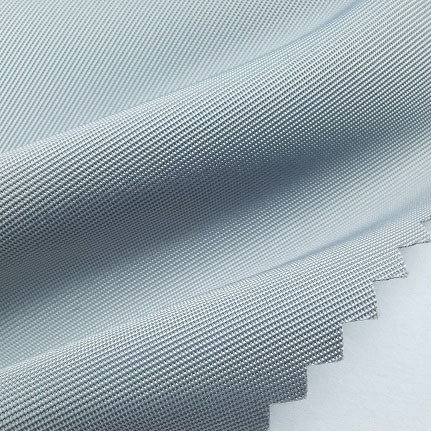

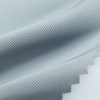

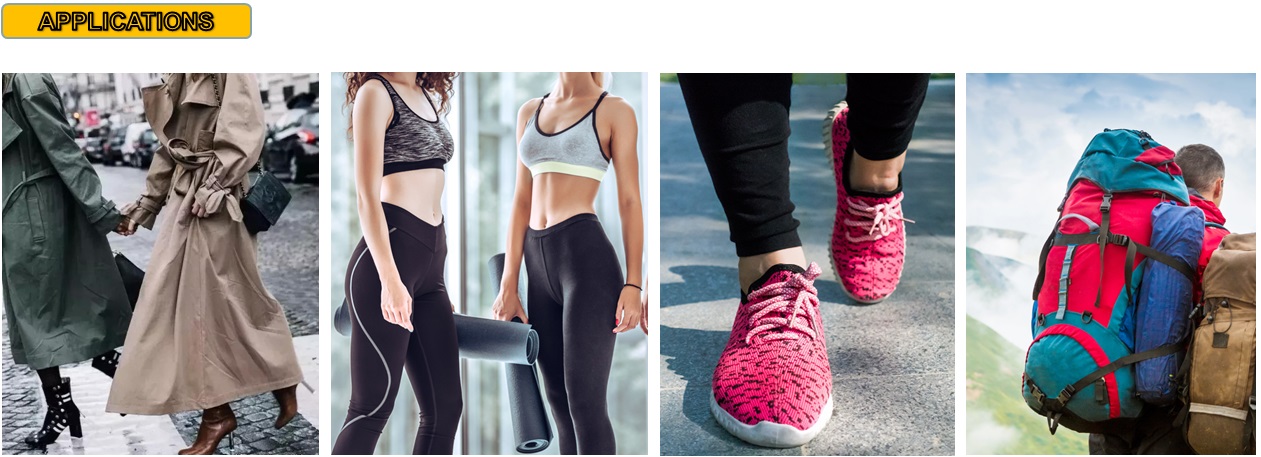

The characteristics of recycled PET 150D anti-wrinkle twill gray poliester fabric for autumn fall density is higher, as one of our basic fabrics,the treatments of this kind fabric is PU coating one time with rich colors , eco-friendly dyes, free of aromatic hydrocarbons and other toxic substances. this fabric is thicker, and the three-dimensional sense of the tissue is stronger,soft and breathable comfortable, Anti-wrinkle no-iron etc, the color is grey or tailor-made dyed, it’s ok to customize colors to your liking. This kind fabric be widely use in different kind of backpack, shoulder bags, Senior clothing and Home textiles. Transaction Certificate (TC) available when order, you can also see our other fabric details on our other pages. Our fabric are popular among customers both at home and abroad.Welcome to contac us to discuss more.

Name : recycled PET 150D anti-wrinkle twill gray poliester fabric for autumn fall Model no. : HYR2900 Material : Polyester Composition : 100% RPET Specifications : 150Dx150D Colour : grey or tailor-made dyed Treatments : PU coating one time Features : 100% RPET, rpet 150D, twill anti-wrinkle fabric, rpet 150D twill anti-wrinkle fabric Width : 150cm GRS certificate : Transaction Certificate (TC) available when order

What is twill fabric?

Warp and weft are interwoven at least once like two yarns. Warp and weft interweaving points are added to change the fabric structure, which is collectively called twill fabric. Twill is the way of fabric manufacturing, the surface of the fabric is relatively plump, in the printing and dyeing process is easy to open shape, that is, we often say that it will not shrink.

Twill fabric, divided into single twill weave and double twill, weft yarn weaving number less than plain, makes the gap between the smaller yarn, yarn can be closely arranged, thereby the fabric density is larger, more thick, good gloss, feel is relatively soft, elasticity is better than plain, the yarn density, thickness under the same conditions, its wear resistance, fastness than plain fabric.

The characteristics of twill cloth.

Twill fabric refers to the warp and weft are interwoven at least once every two yarns, adding warp and weft interweaving points to change the fabric structure. The fabric structure is two up and down twill, 45° left oblique fabric, the front twill is obvious, varietal twill is not obvious on the back. The number of warp and weft yarns is similar, the warp density is slightly higher than the weft density, and the feel is softer than khaki. Twill fabrics are divided into two kinds of coarse twill and fine twill. The characteristics of twill fabric: there are positive and negative points, a complete organization cycle within the interweaving point is less, floating line is longer, feel soft, fabric density is higher, the product is thicker, organization stereo sense is stronger.