SEAQUAL Fabrics

- SEAQUAL fabrics refer to the fabrics made of SEAQUAL® YARN.

- SEAQUAL fabrics contribute to cleaner oceans, preservation of natural resources and re-use post-consumer plastic waste.

- SEAQUAL fabrics are in sharply increasing demand in fashion industry so as to satisfy more and more eco-conscious consumers.

- SEAQUAL fabrics made and supplied from us must contain a minimum of 20% of SEAQUAL® YARN, except in denim where the minimum requirement is 15%.

Up to now, we have been supplying SEAQUAL fabrics woven and knitted with SEAQUAL® YARN, such as TAFFETA 190T, OXFORD 210D, OXFORD 300D/600D, Jersey, elastic fabrics blended with SPANDEX, and so on. It can be mixed with organic cotton, recycled cotton and conventional RPET yarn as well in our mill.

We are proud of our SEAQUAL fabrics on fighting plastic pollution.

In this article, you will find valuable information about SEAQUAL:

All of our SEAQUAL Fabrics are sold and supplied with their unique SEAQUAL Textile Certification Numbers, which are certified by SEAQUAL LAB. They have a good traceability with accurate records (together with supporting documentation) of the products made, used, or sold.

IGO Textile has made a denotion to SEAQUAL INITIATIVE to help fight against marine litter and clean our oceans, and offset our carbon footprint as well. By adapting SEAQUAL fabrics, it brings to your brand the great prestige that you are part of a global community helping to clean our oceans.

Pls just contact us and we would like very much to work out the feasible fabric solution for your special needs.

Who is SEAQUAL?

- In 2016 a Spanish start-up SEAQUAL 4U S.L. (i.e. SEAQUAL) was born of an alliance between ECOALF foundation, textile group SANTANDERINA and spinning mill ANTEX.

- SEAQUAL was created only to undertake the challenge: cleaning the oceans and upcycling plastic waste to extract a new, eco-friendly polyester fiber.

- SEAQUAL is a trademark and is becoming more and more popular in fashion industry.

What is SEAQUAL® YARN?

- SEAQUAL® YARN is an award winning product of textile material, born from SEAQUAL INITIATIVE’s first collaboration with industry.

- SEAQUAL® YARN is a high quality 100% post-consumer recycled polyester yarn containing Upcycled Marine Plastic from SEAQUAL INITIATIVE.

- SEAQUAL® YARN contains approximately 10% Upcycled Marine Plastic (from plastic marine litter), the remaining 90% is post-consumer PET from land sources. Upcycled Marine Plastic is made from marine litter retrieved from our oceans, beaches, rivers and estuaries.

- SEAQUAL® YARN is almost identical in physical properties to virgin polyester and is available in a variety of sizes and finishes (both in continuous filament and staple fiber).

- SEAQUAL® YARN can be blended with natural fibers or used in pure (100%) versions, either greige or yarn-dyed. They meet the requirements of bags, shoes, ready-to-wear, sportswear, denim and even swimwear.

- Although the SEAQUAL YARN offers identical properties and qualities to fibers created using new polyester fiber, its environmental footprint is incomparable. It plays an active role in cleaning up the ocean depths and allows for a 40% reduction in water consumption, energy savings of 50% and reduces carbon emissions by 60%.

- SEAQUAL® YARN is used in a multitude of applications including apparel and accessories, contract and automotive upholstery, home textiles and technical textiles. Polyester fabrics made with SEAQUAL® YARN contribute to cleaner oceans, preservation of natural resources and re-use post-consumer plastic waste.

- SEAQUAL® YARN and products made with SEAQUAL® YARN are manufactured under license.

- SEAQUAL Licensing System

Plastic retrieved from our oceans, beaches and estuaries is converted into a new, fully traceable raw material that has the power to raise awareness of the problem of marine plastics and working hard to solve it. In choosing products containing Upcycled Marine Plastic you are helping to end plastic pollution.

How is SEAQUAL® YARN manufactured?

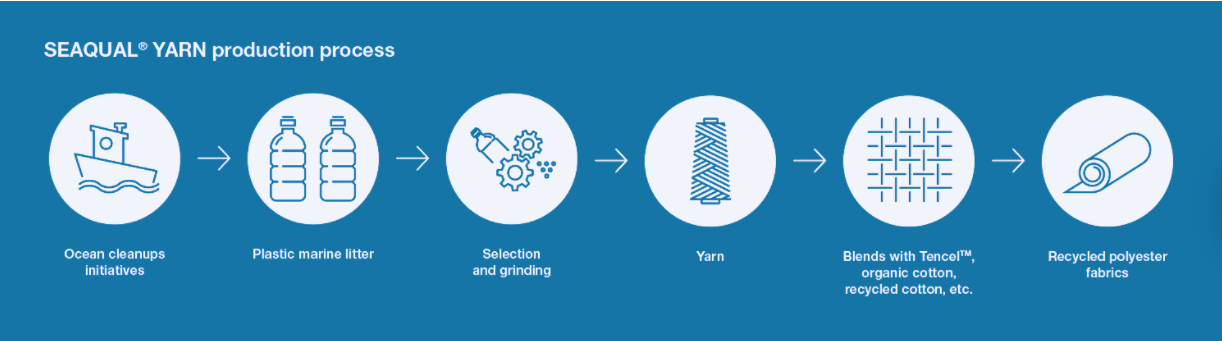

- Ocean clean-ups are to collect the ocean trash or called as marine litter.

- The marine litter is sent by licensed waste management companies to sorting centers approved by SEAQUAL INITIATIVE.

- The waste is sorted into plastics and non-plastics.

- The plastic continues to be sorted into different polymer types.

- Every polymer type is then compressed to be ‘bales’ (a large block) for following transportation.

- The ‘bales’ of PET bottles are then transported to a ‘flake’ producer approved by SEAQUAL INITIATIVE.

- The ‘bales’ of PET bottles are unpacked, and the bottles are shredded into small pieces (also known as ‘flakes’). In this step, other materials like the bottle tops, labels, glues used on the labels and any residual waste, such as sand, are removed and sorteded in a washing process.

- The 100% PET washed ‘flakes’ are then transported to a ‘chip’ manufacturer approved by SEAQUAL INITIATIVE (‘chips’ are also called as ‘nurdles’ or ‘pellets’).

- The chip manufacturer blends the marine litter PET flakes with post-consumer PET flakes from land sources.

- The blended ‘flakes’ are heated until molt and compressed through an extruder, where long noodles spaghetti-like ‘threads’ are formed and then splitted into small lengths or ‘chips’

- The ‘chips’ are sent to the SEAQUAL licensed yarn manufacturer.

- The SEAQUAL licensed yarn manufacturer ‘melt spins’ the polymer chips. Molten polymer is compressed through a spinneret (metal block with tiny holes) and viscous threads fall by gravity, cooling as they fall. Countless threads are manufactured at the same time, with between 34 and 134 threads being used to create each yarn. The threads are mixed and wound onto a bobbin at high speed (about 300km/h).

- The bobbins are sent to the texturing factory, where the yarn is textured.

- The textured yarn is sent to textile manufacturers licensed by SEAQUAL.

- Antex and VICA are currently the only two licensed manufacturers of SEAQUAL® YARN, both are located in Spain. Antex makes continuous filaments and VICA produces short, staple fibers.

- The range of discontinuous yarn can be made in counts from 10nm to 70nm. These can be mixed (according to SEAQUAL’s certification criteria) with natural fibers such as organic cotton, Tencel®, viscose, wool, linen etc. The discontinuous yarn can also be used alone, in their natural ecru shade, or dyed.

- The new continuous range is available as of now in 50, 78, 167 and 340 dtex. Spinning technologies have enabled developments with air texturisation, false twist texturing, mechanical twisting and elasticisation. Yarns can be mass-dyed or dyed on the bobbin. Suitable for ready-to-wear, beachwear, sportswear, denim and socks, these yarns can be woven, or knitted using circular or seamless machines.

What is SEAQUAL INITIATIVE?

In 2019, we participated in SEAQUAL INITIATIVE.

- SEAQUAL operates SEAQUAL INITIATIVE.

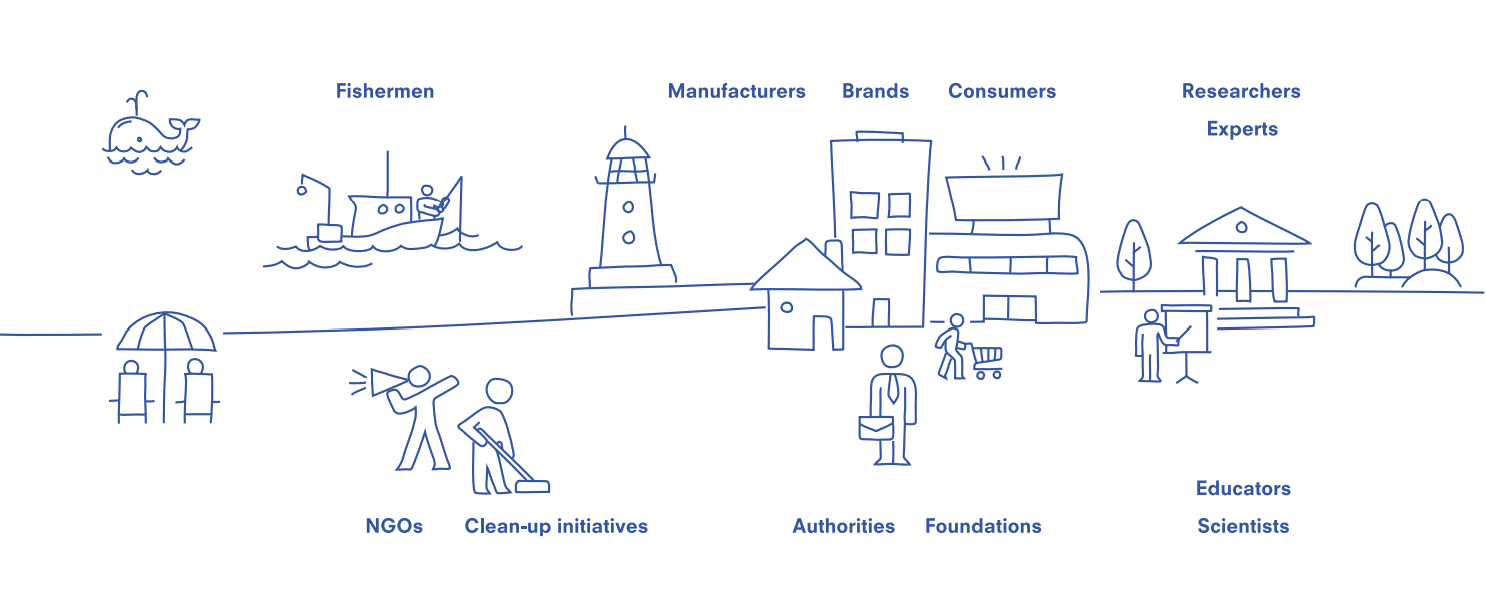

- SEAQUAL INITIATIVE is a unique collaborative community helping to fight marine plastic pollution.

- SEAQUAL INITIATIVE voices an emotion and a commitment to fight plastic pollution and help local communities move towards a circular economy.

- SEAQUAL INITIATIVE collaborates with NGOs, Fishermen, Researchers, Scientists, Authorities, Brands and Manufacturers to clean our oceans of marine litter.

- SEAQUAL INITIATIVE works with ocean clean-ups around the world to bring value to the waste that they recover. Some of the plastic types found in marine litter include a polyester commonly used in plastic bottles called PET (Polyethylene Terephthalate), polyamide – also known as nylon, polypropylene, and polyethylene.

- SEAQUAL INITIATIVE removes all types of marine litter from the the ocean, not just PET but also PP, PA, metal, rubber, glass and other materials. The PET is used to produce SEAQUAL FIBER.

- SEAQUAL is also working to upcycle the PP and the PA and is exploring ways to revalue to HDPE and LDPE too. All the other materials are sorted and recycled by the partners. By choosing SEAQUAL FIBER or SEAQUAL certified products you are helping to remove all types of marine litter.

- SEAQUAL INITIATIVE’s first collaboration with industry resulted in the award winning SEAQUAL® YARN, a high quality 100% recycled polyester fiber containing plastic marine litter.

- SEAQUAL INITIATIVE works with the waste management and recycling industries to transform marine litter into SEAQUAL® MARINE PLASTIC, so that leading brands and manufacturers can create inspiring sustainable products.

- In a word, SEAQUAL INITIATIVE is a unique collaborative community that works with ocean clean-up programs around the world to transform the marine litter they recover into Upcycled Marine Plastic; a new, fully traceable raw material with the power to raise awareness of the issue of marine pollution and highlight those helping to fight it. In choosing products containing Upcycled Marine Plastic, you are helping to clean our oceans.

- A key objective of SEAQUAL INITIATIVE is to raise awareness of the issues facing our oceans and coastal communities, as such all parties involved in the supply chain, such as manufacturers, brands, distributors, and retailers shall mention SEAQUAL INITIATIVE in their marketing materials, such as web pages, social media, media press and merchandising.

SEAQUAL INITIATIVE is based on 4 pillars:

- Recycling PLASTIC MARINE LITTER and INDUSTRIAL MARINE PLASTICS: Enabling the retrieving, collecting, and sorting of PLASTIC MARINE LITTER and INDUSTRIAL MARINE PLASTICS by engaging NGOs, fisheries, local communities, authorities, and waste management companies.

- Engaging industries: Engaging recyclers, manufacturers, and brands to transform PLASTIC MARINE LITTER and INDUSTRIAL MARINE PLASTICS into SEAQUAL MARINE PLASTIC and then into PRODUCTS.

- Communicating: Raising awareness of the plastic pollution issue by informing industries, lobbying authorities, and educating and sensitizing society.

- Inspiring consumers and communities: It is essential that consumers are aware that the product they are purchasing/receiving contains SEAQUAL MARINE PLASTIC and that they are supporting SEAQUAL INITIATIVE in its fight against marine litter.

SEAQUAL INITIATIVE promotes circularity in coastal communities and fights plastic pollution by creating value in waste. By supporting SEAQUAL INITIATIVE you are helping to clean our oceans, support local communities and move society towards a circular economy.

SEAQUAL INITIATIVE & OCEAN CLEAN-UPS

SEAQUAL INITIATIVE works with ocean clean-ups around the world, to bring value to the waste they recover.

Worldwide, there are a growing number of ocean clean-ups working hard to retrieve marine litter from our oceans, beaches, rivers and estuaries. Ocean clean-ups can be anything from small groups of local volunteers, all the way through to large international programs. They can be one-off beach clean-ups or involve whole communities of fishermen retrieving waste on a regular basis.

These ocean clean-ups collect all types of waste; plastics, metals, glass, rubber, and mixed material items – everything from shoes to refrigerators! Because mixed waste is expensive to recycle, in the past much of this waste was destined to landfill or incineration.

SEAQUAL INITIATIVE is dedicated to giving a second life to this material. At SEAQUAL INITIATIVE we don’t look for materials to recycle, we recycle the materials we find. This mixed waste is sorted into different material types; materials such as metals and glass are recycled through traditional routes, while organic material and other non-plastics are recycled or disposed of responsibly. Marine plastics are harder to recycle. Although plastics can survive in the ocean for hundreds of years, UV rays, salt water and friction mean they can degrade quickly.

SEAQUAL INITIATIVE is dedicated to giving a new life to all types of marine plastic. The types of plastics found and the ratio of plastics to other materials depends upon many factors, including the type of ocean clean-up, the region and the season. Typically, beach clean-ups have higher percentages of plastics, because the waste has been carried there by the tides; for example, PET water bottles may represent 40% of waste collected on some beaches, but only 5-10% of the waste collected from the ocean floor by fishermen.

SEAQUAL INITIATIVE is a community of individuals, organizations and companies working together to help clean our oceans, raise awareness of the issue of marine litter and highlight those helping to fight it.

Applications of SEAQUAL

Textile and apparel brands and sales enterprises, such as Uniqlo, Adidas, Zara, H&M and Decathlon, have formulated their own adjustment plans for apparel industry chain and carried out GRS and Eco-Cycle certification, aiming at the increasingly important issue of environmental protection and recycling of clothing. Environmental protection yarn, SEAQUAL YARN and other recycled yarns are in short supply. In the next few years, “recycled textiles” will become one of the mainstream trends in related industries, just like recycled paper and recycled plastics.

SEAQUAL FINAL PRODUCT refers to any finished product ready for retail or end use that contains SEAQUAL® MARINE PLASTIC including SEAQUAL® POLYMER, SEAQUAL® FIBER and SEAQUAL® YARN.

For example, SEAQUAL fabric is one of the most applied SEAQUAL FINAL PRODUCTS. It is the woven or knitted textile product which is fully or partially made with SEAQUAL YARN. SEAQUAL fabrics contribute to cleaner oceans, preservation of natural resources and re-use post-consumer plastic waste.

SEAQUAL is becoming more and more popular in the fashion and textile industry since its birth and has become a mostly used synthetic yarn. It’s regarded as an eco-friendly material which is much better than plastics produced directly from crude oil.

SEAQUAL is one of the most certified, earth friendly fibres in the world. SEAQUAL is high quality recycled polyester yarn made from 100% recycled materials including post consumer plastic bottles and plastic captured from the sea, that’s why it contributes to preserving natural resources and reducing the waste in the planet’s water.

SEAQUAL selects plastic from the Mediterranean to obtain PET (polyethyleneterephthalate) chips or pellets;

SEAQUAL helps clean rubbish from the oceans with the aid of fishermen;

SEAQUAL turns plastic into polyester yarn to make fabrics.

At the weaving phase, the polyester of marine origin is mixed with other ecological, natural, recycled or recovered fibres.

SEAQUAL applies ecological dyes and finishes based on saving water and energy, completing a vertical, eco-friendly process.

Nowadays you could find SEAQUAL Final Products in different applications and in different sectors, such as Bags (textile & leather), Accessories, Fashion clothing, Swimwear, Sportswear, Outdoor clothing, Ready to wear , Socks/hosiery, Denim clothing, Workwear/corporate wear, Personal protective equipment, Footwear , Other Apparel Textiles, Intimates/lingerie, Automotive Interior Textiles (Upholstery & carpet), Home Textiles (Bed Linen, Mattress, Curtains, Floor Covering, Upholstery).

SEAQUAL Final Products and their applications are listed as below:

TEXTILE – Interior

Automotive Interior Textiles (Upholstery & carpet)

Contract Furnishing Textiles (Upholstery, Wall Coverings, Floor Coverings)

Home Textiles (Bed Linen, Mattress, Curtains, Floor Covering, Upholstery)

Other Interior Textiles

TEXTILE – Apparel

Fashion clothing

Swimwear

Sportswear

Outdoor clothing

Intimates/lingerie

Ready to wear

Socks/hosiery

Denim clothing

Workwear/corporate wear

Personal protective equipment

Footwear

Bags (textile & leather)

Accessories

Other Apparel Textiles

TEXTILE – Technical/Industrial

Exterior upholstery textiles

Exterior blinds/sun protection

Automotive textiles (excluding interior upholstery & carpets)

Medical textiles

Sports equipment textiles (excluding clothing)

Construction textiles

Textiles for composite materials

Non-woven textiles

Textiles for packaging

Other Industrial textiles

NON-TEXTILE

Aerospace / Transport Industry

Agriculture & Fishing Industries

Beauty & Cosmetics Industry

Construction Industry

Education Industry

Energy Industry

Entertainment, Media & Creative Industries

Financial Services Industry

Food & Drinks Industry

Healthcare Industry

Hospitality Industry

Manufacturing Industry

Retail Industry

Technology & Telecommunication Industries

Other Non-Textile Industries

Our oceans are our greatest shared natural resource.

Together we can clean, repair and protect them.

Your purchasing power is one of the most powerful tools for change. Use it wisely.

–